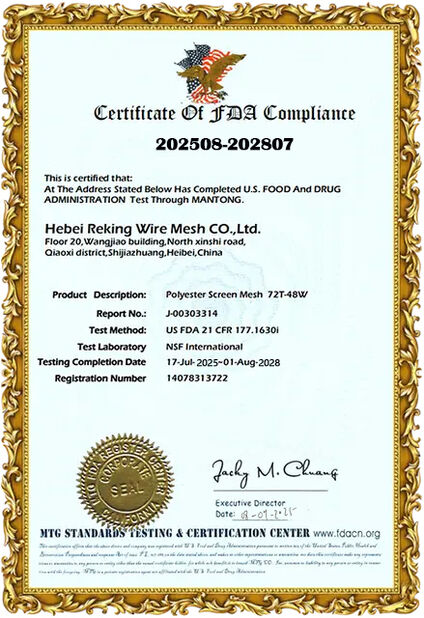

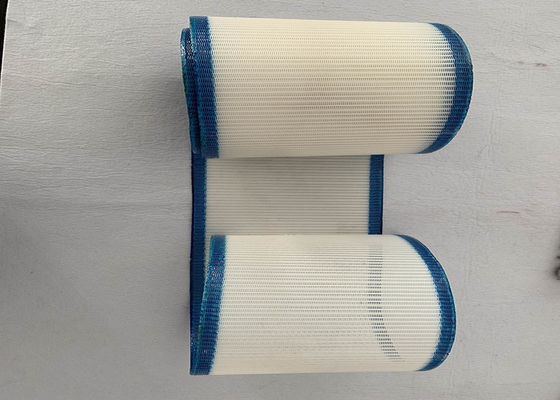

Faisceau de fabrication de papier pour déshydrateurs, faisceau en polyester, bande de faisceau de déshydratation de pulpe de lavage

Présentation du produit:

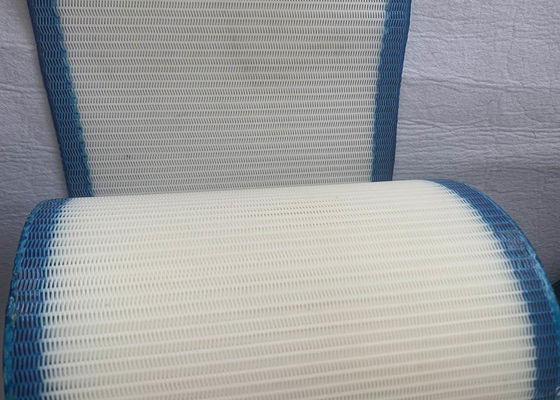

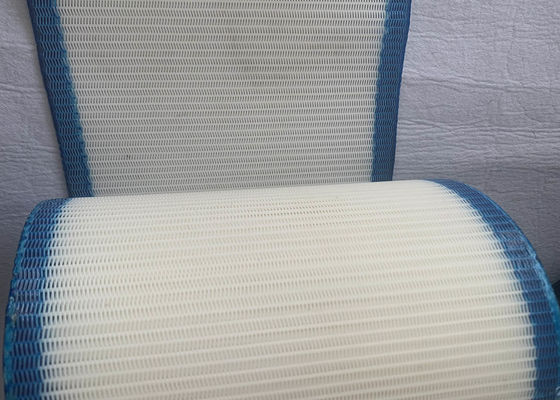

Le maillage de polyester est un textile industriel essentiel largement utilisé dans la fabrication du papier, la protection de l'environnement et les industries des tissus non tissés, célébré pour ses excellentes propriétés mécaniques,stabilité chimiqueCette maille est fabriquée à partir de filaments de polyester de haute qualité (typiquement PET, polyéthylène téréphtalate) et présente une résistance exceptionnelle à l'abrasion, à l'hydrolyse, à l'usure, à la corrosion et à la corrosion.La plupart des solvants organiques le rendent adapté à une utilisation à long terme dans des conditions humides., des environnements à haute température et chimiquement actifs, un avantage clé par rapport aux mailles métalliques ou en nylon traditionnelles.

Le procédé de fabrication des mailles de formation en polyester implique un tissage de précision à l'aide de métiers à tisser avancés à rapière ou à jet d'air,suivi d'un traitement thermique et de surface pour améliorer la stabilité dimensionnelle et la résistance à l'usureSa structure est principalement divisée en conceptions monocouche, double couche et multicouche.est idéal pour la production de papiers minces comme le papier tissé et le papier de culture, assurant un drainage uniforme de l'eau et une surface de papier lisse.offrent une résistance mécanique et une capacité de charge plus élevéesLes principaux paramètres de la maille sont la taille de l'ouverture (de 0,01 à 0,05 mm) et la taille de la surface de l'ouverture (de 0,01 à 0,05 mm).1 mm à 5 mm), le nombre de mailles (20-200 fils par pouce) et l'épaisseur (0,3 mm-5 mm) peuvent être personnalisés pour répondre aux exigences de production spécifiques.

Dans les applications pratiques, le maillage de formation en polyester joue un rôle irremplaçable.supportant la suspension en fibresEn ce qui concerne la protection de l'environnement, la qualité du papier et l'efficacité de la production sont améliorées.il est utilisé dans les presses à filtres à courroie et les filtres sous vide pour le déshydratage des boues dans le traitement des eaux usées municipales et le traitement des eaux usées industrielles, séparant efficacement les phases solide et liquide avec de faibles coûts de maintenance.Il trouve des applications dans la production de tissus non tissés (en tant que substrat de formage) et la transformation alimentaire (pour le filtrage et le transport), conformément aux normes de sécurité alimentaire).

Comparé aux matériaux alternatifs, le maillage en polyester offre des avantages distincts: il est léger, réduisant la charge sur l'équipement; il a un faible frottement, réduisant la consommation d'énergie;et il est facile à nettoyerAvec ses spécifications personnalisables, ses excellentes performances et sa large gamme d'applications,Le maillage en polyester est devenu un matériau essentiel pour la production industrielle moderne, répondant aux normes élevées d'efficacité, de durabilité et de protection de l'environnement exigées par divers secteurs.

.

Tableau des paramètres

Diamètre du fil ((mm) |

Durabilité

Résistance

(N/cm) |

Le poids

Poids de l'équipement |

Épaisseur

mm |

L'air

Perméabilité

M3/m2h |

MFC

127/pa |

Spirale

fil de fer |

Connexion

fil de fer |

Filtreur

le matériel

monofilaments |

| 0.50 |

0.80 |

0.60*3 |

1800 |

1.50 |

2.1 |

4480 |

280 |

| 0.68 |

0.90 |

0.80*4 |

2000 |

2.0 |

2.45 |

6080 |

380 |

| 0.68 |

0.90 |

0.90*3 |

2000 |

190 |

2.45 |

5760 |

360 |

| 0.68 |

0.90 |

0.80*3 |

2000 |

1.85 |

2.45 |

7750 |

484 |

| 0.68 |

0.90 |

Le fil plat2.10.80 |

2000 |

1.80 |

2.45 |

9oo0 |

563 |

| 0.68 |

0.90 |

Le fil plat2.40.88 |

2000 |

1.85 |

2.45 |

8000 |

500 |

| 0.68 |

0.90 |

Fil de carbone conducteur |

2000 |

1.60 |

2.45 |

10000 |

625 |

| 0.90 |

0.90 |

0.90*3 |

2300 |

2.30 |

3.03 |

7500 |

468 |

| 0.90 |

1.10 |

1.04 |

2000 |

2.40 |

3.15 |

6240 |

390 |

| 0.90 |

1.10 |

1.23 |

2000 |

2.25 |

3.15 |

6240 |

390 |

| 1.0 |

0.90 |

1.0*3 |

2000 |

2.50 |

3.60 |

5000 |

315 |

| 1.20 |

1.30 |

1.2'3 |

2600 |

2.85 |

4.30 |

7500 |

468 |

Application du produit

Le maillage de polyester trouve des applications diverses: dans la fabrication du papier, il aide à la formation de feuilles; dans le traitement des eaux usées, il filtre les impuretés. Il tamise les aliments, sépare dans les produits pharmaceutiques,et permet une sérigraphie, améliorant l'efficacité dans tous les secteurs.

Avantages du produit

Les bords du tamis sont lissés par étanchéité thermique, renforcés d'une largeur d'environ 4 cm par un adhésif flexible à deux composants.Les tamis sont reliés dans une bande sans fin par un joint de tondeuse en acier inoxydable (AISI 316) démontableUne autre option pour connecter le tamis à une bande sans fin est un joint tissé non séparable, qui a une durée de vie plus longue que le joint à pince,mais ne peut être utilisé que sur des machines qui permettent l'installation d'une ceinture sans fin.

Les écrans filtrants sont utilisés comme bandes sans fin reliées par un joint amovible ou non amovible.

Les bords des écrans filtrants sont fondus et renforcés par un adhésif flexible à deux composants résistant mécaniquement.Le renforcement triangulaire du joint aux bords du tamis augmente la résistance mécanique du joint.

Nous sommes un fabricant professionnel et fournisseur de filtres en nylon et en polyester.

Avec tous les objets disponibles et la taille dont vous avez besoin.

Emballage et livraison

Le transport maritime commun:

1.pour une petite quantité, expédiée par courrier.

2Pour les grandes quantités, transportées par voie aérienne ou maritime.

3.le numéro de suivi vous sera envoyé par e-mail après que la commande ait été expédiée.

4.Si vous avez un transitaire en Chine, nous pouvons envoyer à votre transitaire gratuitement.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!